Today’s cars are not only welded together in many different ways, but are comprised of many different types of metals and plastics, too. Knowing the correct application, and choosing the right welder for the job, is very important and is the reason we have several types of welders. Our Resistance Spot Welder, which allows us to duplicate factory spot welds, runs on more power than the main wires used to supply your whole house and cost over $20,000! That’s just one welder.

We have two MIG welders, a TIG welder, and even a Nitrogen Plastic Welder. There is also a welder that does Silicon Bronze and another one that does Aluminum. Cars today use a lot of panel bonding which is close to welding but it is really a glue bonding process. We even have an electro-magnetic induction heater that is used to remove these bonded panels. Knowing the right welder for the right job is critical and is what we do.

Painting is a specialized field requiring special skills that are able to contend with variables associated with each and every job. There are different procedures and products that need to be known before painting a surface. The painter must know product content to determine what is going to adhere to the surface being painted. You’d have a mess if the same product was used on an aluminum surface that was used on plastic.

There are many variables that effect painting. The compressed air we use is refrigerated to remove moisture and is then filtered. Compressed air is so important that we’ve invested over $20,000 in this system. The spray booth is a tool that is used to control variables.

We have a unique paint booth, designed ourselves, that has received International recognition. In fact, calls have come in from as far away as Australia inquiring as to what we did and how we did it. You can read more about this in the section labeled “In The News”. Tools and training are important.

Having the ability to go into a special mindset is equally important. The painter has to pay attention the entire time and be able to make adjustments as he goes. We are very proud of our painter.

If anyone tells you that color matching is easy, you’re being lied to. There could be as many as twenty or more different formulas available for the color code on your car. Ordering a can of paint for your color code is not good enough for us. Matching the color your car “is” is what matters. First, we find out what plant your car came from. Then we use a color reading camera, along with color alternate chips, to mix the color ourselves.

A color spray out panel is then used to compare the color made to the color on your car. If necessary, the process will be repeated until it’s right. Our goal is to have your car look like it wasn’t in an accident, and a lot of effort goes into achieving that result. We probably have over $70,000 invested in color matching equipment and is very important to us.

It is easy to bolt on a new panel, but many panels aren’t bolted on. What is best for your car may be to repair a panel, not replace it. It does take time to go through the process. If we repair a panel, we expect the repair to last as long as the rest of the car does. If we don’t feel we can get it all better, we will tell you so. A lot of panels can be repaired to “not noticeable” for less cost than replacement. We can give you the real scoop on the pro’s and con’s of the repair process. Every panel is different and we will let you know what is involved in the straightening procedure. A lot of it is part science and part art.

Our shop has a work station dedicated to plastic repair. We have a Nitrogen Welder used specifically for welding plastic parts and bumpers. There are procedures for repairing plastic, but they are not as good as replacing the part. We repair a lot of plastic parts that are expensive to replace and our customers benefit from the cost savings. It is amazing what we can do with plastic. A lot of bumpers can be repaired and made better at so little cost. We know what is a candidate for repair and what is not repairable. Knowing the pro’s and con’s enable our customers to make the proper decision themselves.

We are certified and equipped to do A/C repair. Collision A/C repair is a piece of cake compared to repairing old worn out systems. Repairing old systems have a high failure rate because of the amount of parts that need to be replaced. Why? Because the entire system is the same age. We try not to get involved with these aging systems because we want very much to have happy customers. We have years of experience repairing collision damaged A/C systems. If the parts are damaged, we replace them, and we are considered heroes.

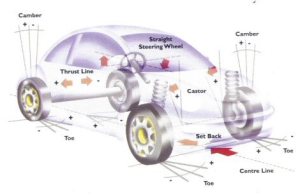

Some places offer free wheel alignments. In our world, that means “Set the tow and let it go” That isn’t what we do. We may spend hours aligning just one car. We correct what others can’t. If the car will not align, that means something is wrong. We can even straighten the frame it that’s the cause. Our shop has a Hunter Four Wheel Laser Alignment machine. In our opinion, there is no reason a car cannot be aligned.

Changing tires equipped with tire pressure monitors are tricky. We have a new style tire machine that protects the pressure sensor. Balancing is done with a Computerized Spin Balancer. Our shop has these machines so we can maintain quick turnaround times and ensure no untimely delays in the collision repair process. We are not a tire shop, but are always here and willing to help.

This is an area where you can go wrong with doing it yourself. Beware of “It’s a small scratch or dent – I should be able to fix it myself”. If it is easy, it should be able to be fixed inexpensively. We show many people how to do things themselves and also know when it’s not advisable to do so. Our desire is to help. There is no dent that is too small. If it bothers you, it is important. There are often different approaches that could be taken. We throw those ideas around so that you can choose the one that’s right for you.

We accept: cash, check & debit/credit cards